As a Heavy Equipment Operator, you might only think about the equipment that is used to build such amazing things. Who is to say what gear is required and what work it is scheduled to complete within the provided timeline while at the job site. It is the process behind the scenes of a project that is more interesting to me than the actual operation of equipment. The following information are just a few aspects of a project site that I want to be a bigger part of and why.

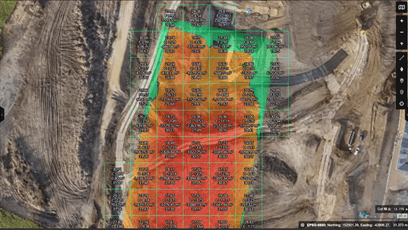

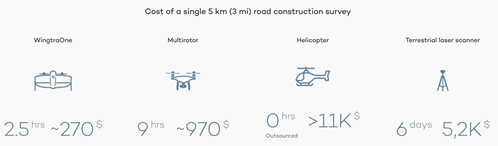

The first aspect of a project is to know what needs to be built. If your project is to build a road, to connect point A to point B, what is required. In order to design this road, it requires a site survey and surveying equipment. You will need to visit the project site and gather as much information that is required. Some of the information that you are looking for is the current soil state (whether the soil is in a bank form, loose form or a compacted form), the soil shape and the gradation of the soil. These three pieces of information has a tremendous impact when calculating the estimations for the project. Once the gathered information is collected you can move onto the next stage of the project planning process which is organizing.

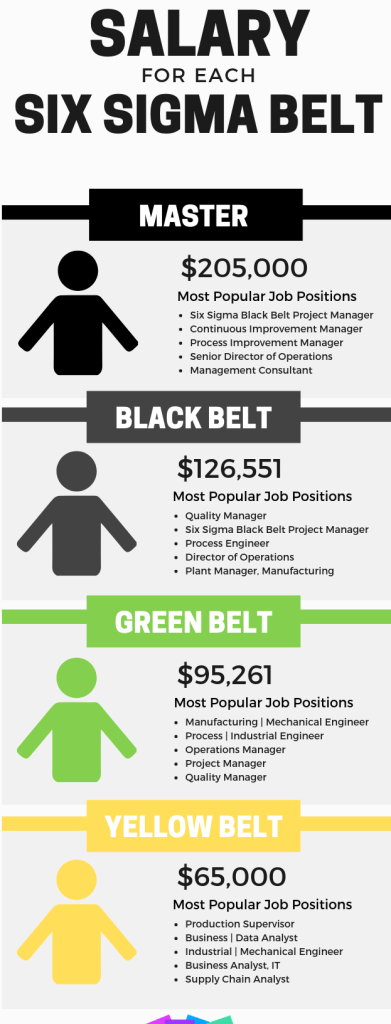

When you enter the organizing stage of the project process, you can start to build a flow chart. There are many factors that need to be addressed when building a chart. You must identify the construction requirements, limitations and restrictions. An important step in the organizing process is staffing. Developing a personnel roster is vital to the process as it will also effect the calculations of the estimations that will be drawn up. The estimations will be effected due to the operators experience level with the assigned tasks.

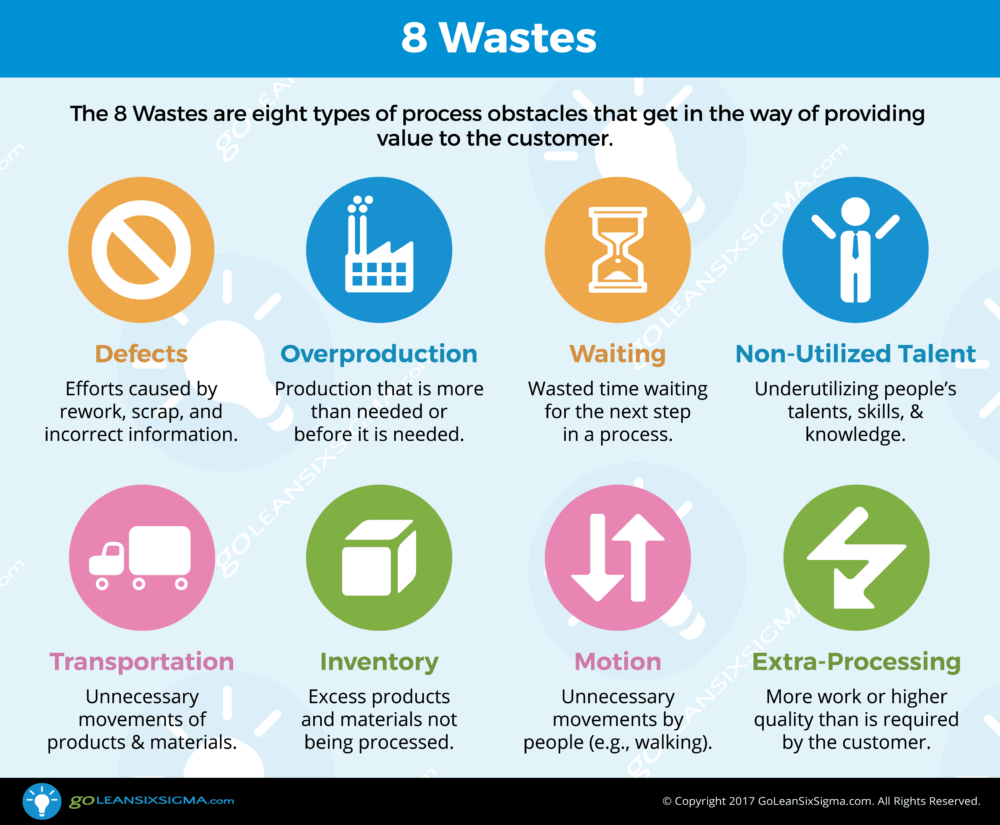

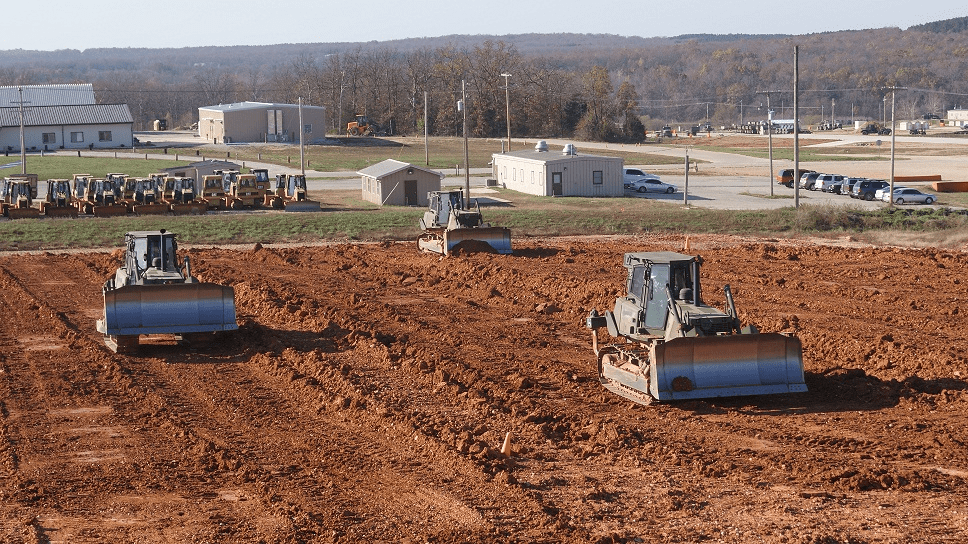

The next few processes of the project are focused more on actual project management. This is where an individual will conduct the directing, controlling and executing of the project. The experience that these last few stages provide to you is essential for a project manager. In these stages the project manager must issue the orders to the chiefs and team leaders, request support from any external companies in the form of transportation, fuel, oils, as requirements needed. You must also deliver daily safety briefs and bench marks, and periodically supervise crews and teams. All of the previously mentioned stages provide exceptional experience that will help with a furthered career in the Marine Corps as well as the transfer to civilian contracting if that time comes.