You might be wondering what Lean Six Sigma is. The Lean Six Sigma website states that “it is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time, while promoting the use of work standardization and flow, thereby creating a competitive advantage. It applies anywhere variation and waste exist, and every employee should be involved.” I have had the opportunity to work with Lean Six Sigma in my previous job, however I had forgotten about it, until recently when the Marine Corps sent me to a short and quick introduction to this program.

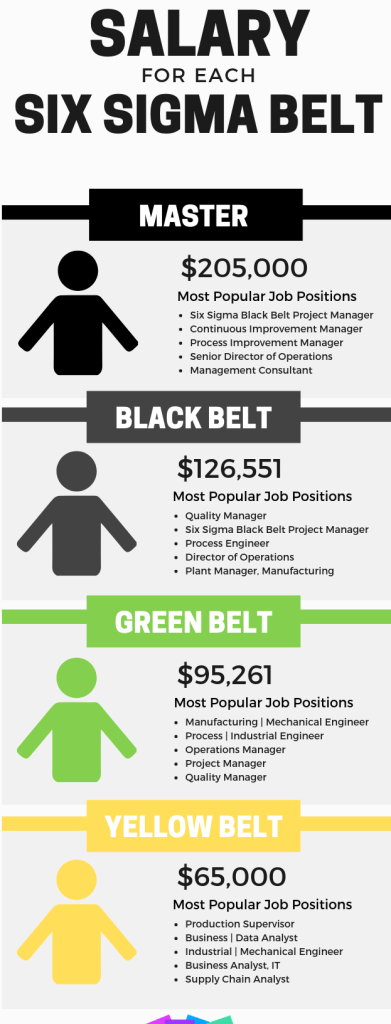

So what are some benefits for you? Well, lets start with money because that is what most of us if not all of us love. There are different levels that the program calls “belts,” there is the yellow belt, green belt, black belt, and master black belt. With a yellow belt an individual could earn up to $65,000 for an annual income. A green belt has an annual income of $95,261; a black belt is $126,551 annual income. The last belt is significantly more, is it $205,000 annual income. However, one has to earn each belt to progress to the next, and there are fees included in taking the courses as well as the exams. However, it seems totally worth it to me, because of the program itself helps the flow of a company. The money is not the only thing that interests me with this program, I did not realize the true impact that it could make to a job. I had a ton of ideas on how to improve my job however I did not understand the process of how to implement those ideas into a process.

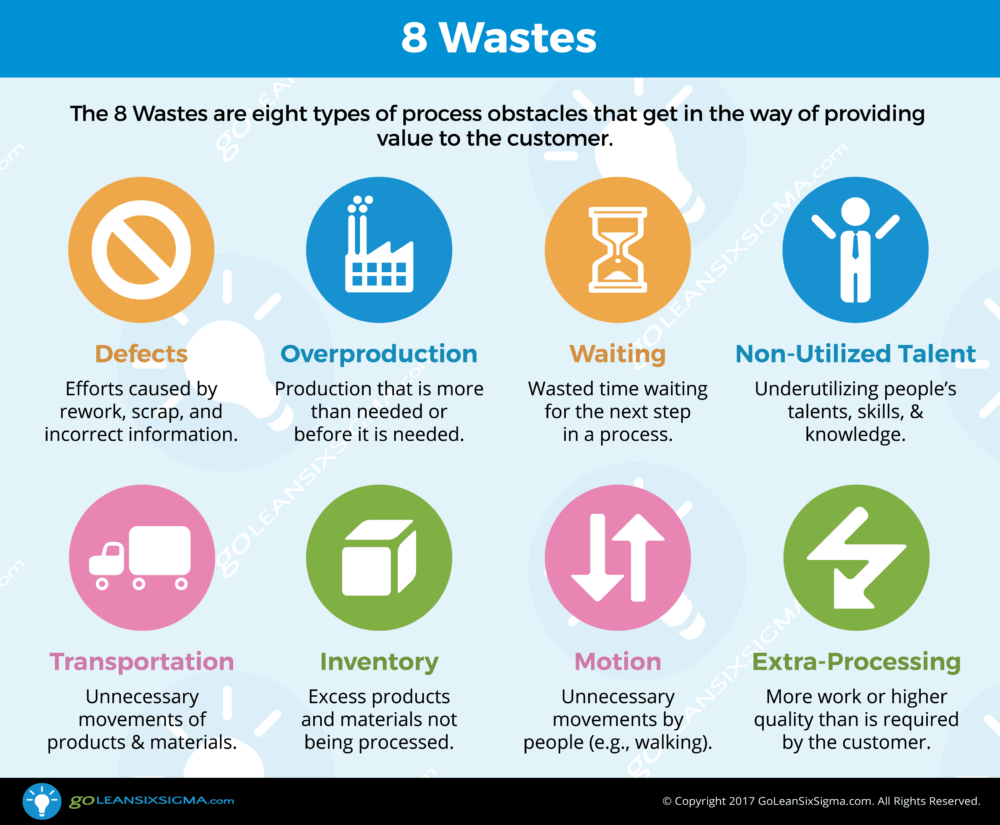

If you are the type of person that has tried to improve your company’s processes and policies but direct supervision of your position has denied your ideas for whatever reason than look into Lean Six Sigma. These are special employment opportunities where you and maybe a team of other certified belt holders review the current progress and adapt the company to preventing waste. I did this at my previous job before I joined the United States Marine Corps. It was a car dealership where we purchased vehicles from auction and rebuilt them for a resale. There was a lot of waste in this process as the stages of the vehicles might be far away from the building and employees would have to walk further to get to the next vehicle. We fixed this by moving certain stages closer to the building, preventing employees from walking too far. The extra time that was spent of walking was not spent on a little more work or diagnosis of a problem the vehicle was having.

If you are the type of person that has tried to improve your company’s processes and policies but direct supervision of your position has denied your ideas for whatever reason than look into Lean Six Sigma. These are special employment opportunities where you and maybe a team of other certified belt holders review the current progress and adapt the company to preventing waste. I did this at my previous job before I joined the United States Marine Corps. It was a car dealership where we purchased vehicles from auction and rebuilt them for a resale. There was a lot of waste in this process as the stages of the vehicles might be far away from the building and employees would have to walk further to get to the next vehicle. We fixed this by moving certain stages closer to the building, preventing employees from walking too far. The extra time that was spent of walking was not spent on a little more work or diagnosis of a problem the vehicle was having.

I plan to take these courses to earn a belt or two or even more. I am a hand on worker, but if I can achieve earning a belt then I feel I would be a dual threat for a company. I feel in my opinion that most management did not spend a ton of time in the lower section of a work environment. They are the ones that see the big picture quicker and are promoted, but they are not the best subject matter experts. Again, this is in my experience and my opinion. For example, in the Marine Corps there is enlisted marines and commissioned officers. A new officer is a 21-24 year old that does not know how things work around a shop. They just learn how to lead and be in charge. The best officers that I have encountered are the ones that make the transition from enlisted to commissioned. However there are good fresh commissioned officers. This is what I plan on doing, I have one more semester left and I will be putting in a package to become a commissioned officer. If accepted, I will also take these Lean Six Sigma courses and earn myself a belt to help me lead my potential future shop in being the best that they can be, and helping myself be the best that I can be.